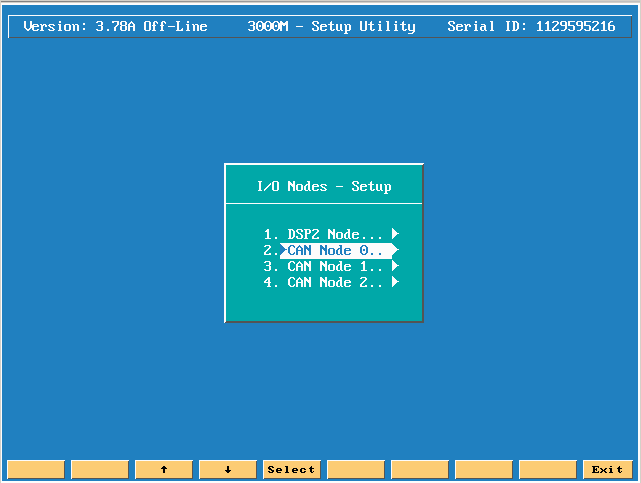

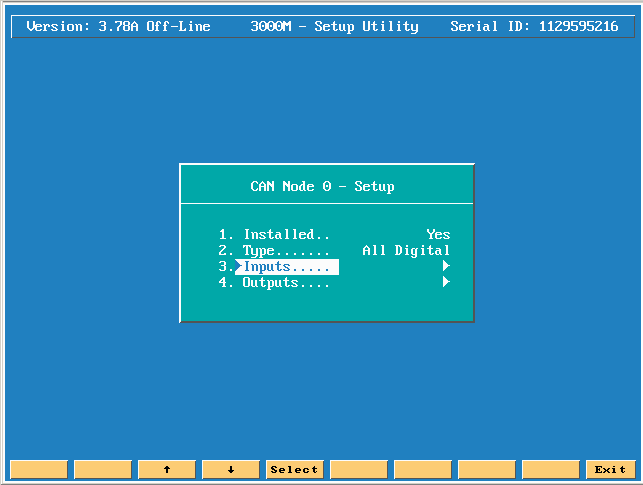

Can Node 0 setup info:

Press enter on Can Node 0 to see the next menu.

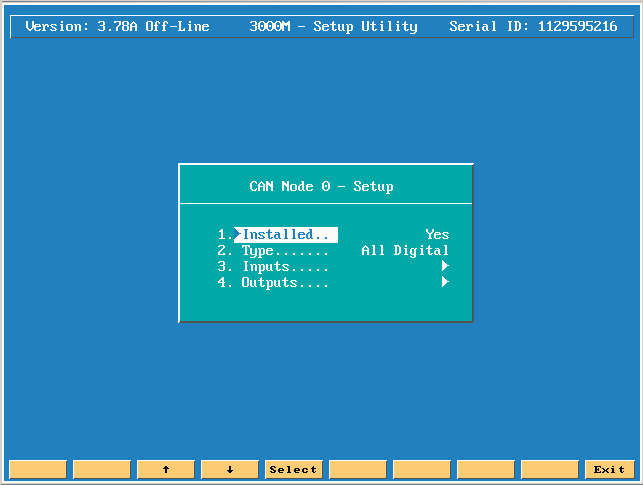

Can Node 0 should always say installed Yes!

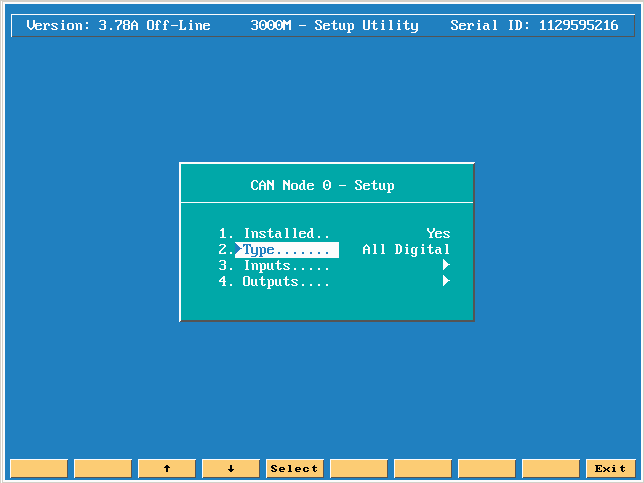

Move down to Type and press the enter key to see the options. All Digital is the Default.

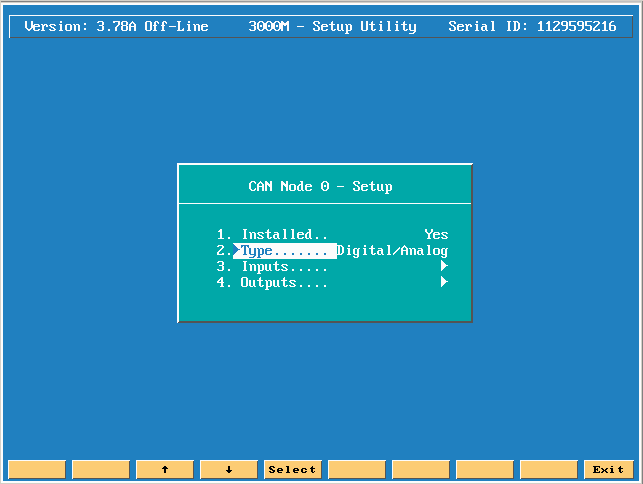

Type Digital/Analog would allow you to put a Spindle load meter up on the CNC screen, however it causes the last output bit #5 to change from an output to become an input. This will cause the coolant option to not work anymore unless you reassign its output to another available output port and move the wire to the new corresponding position like output bit 2 for example.

Move down to inputs and press the enter key to see the next menu.

Click on the link to see ![]() Inputs menu setup information.

Inputs menu setup information.

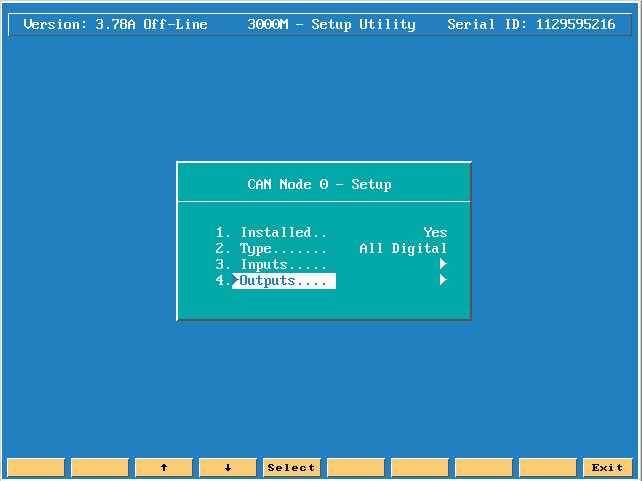

Move down to outputs and press the enter key to see the next menu.

Click on the link to see ![]() Outputs menu setup information.

Outputs menu setup information.

When you first boot up the 3000 and you go to the CNC screen at the bottom there is a message screen. It should say calibrating can bus IO. Then the next message should be DSP2 + either 1 or 2 nodes detected! If you have 2 nodes, then this means there is a second can bus board attached to the system. On an older 3300MK this second board is up in the console mounted to the top rear of the sheet metal of the CRT. This board was used for the Handy Pulsar option.