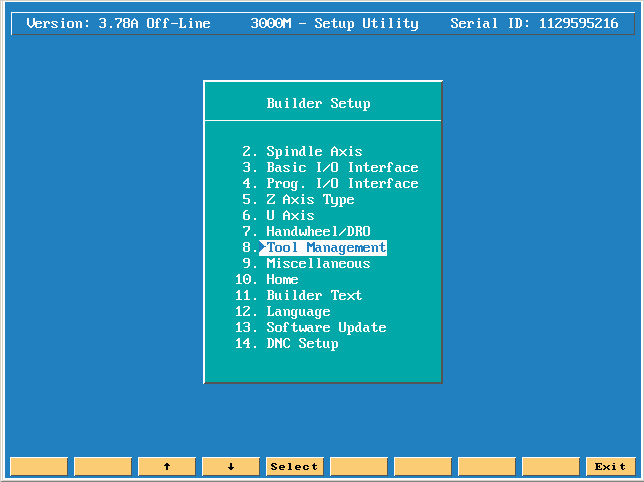

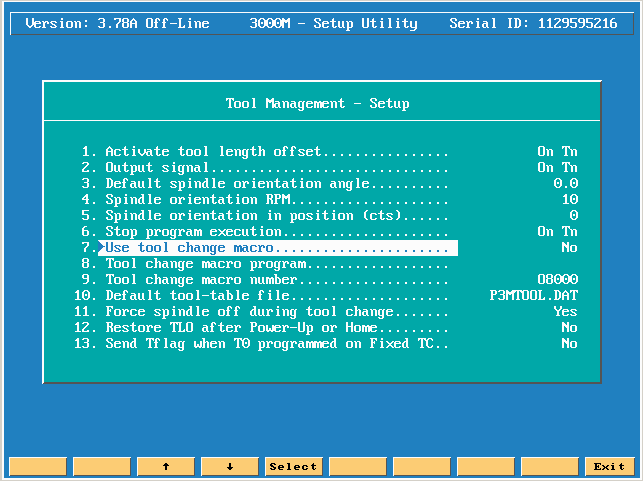

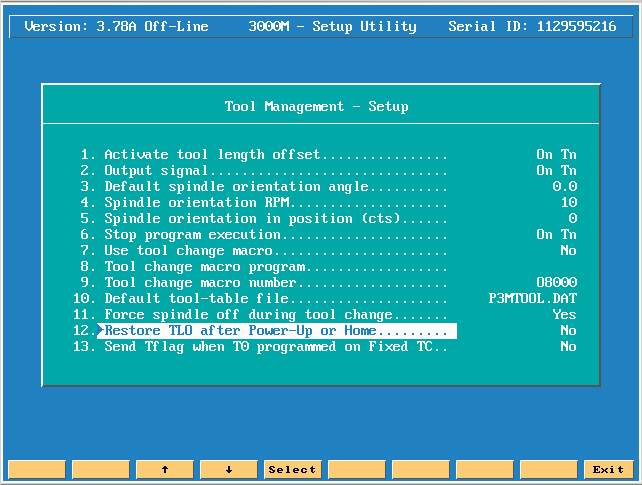

Tool Management setup info:

Press the enter key on Tool Management option.

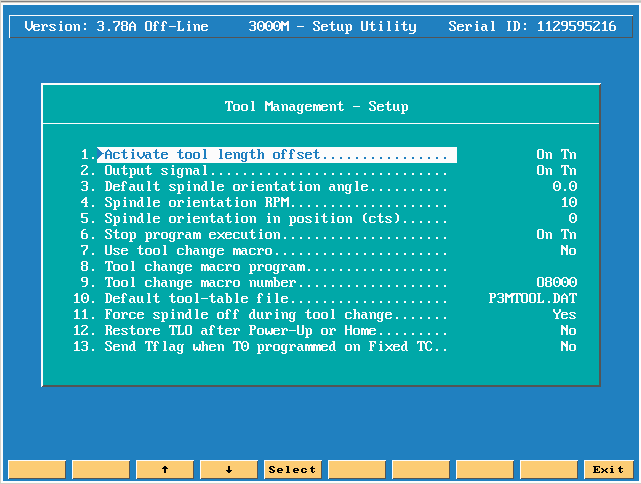

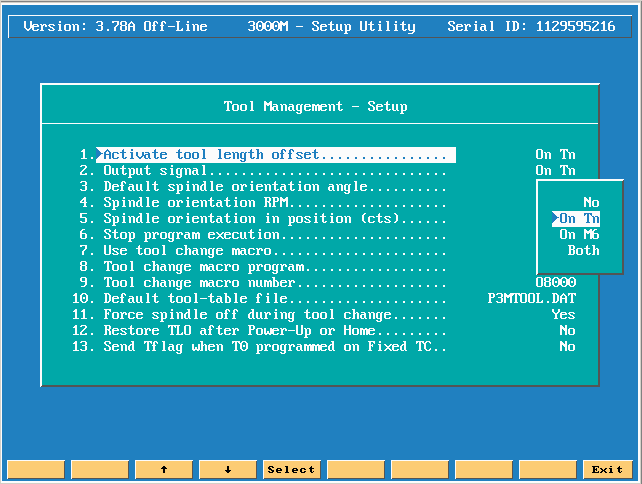

Press the enter key on Activate Tool length offset to see the next option menu.

|

Setting |

Description |

|

No |

Function is not used. |

|

On Tn |

Function activates only when a tool is activated (T-Word). |

|

On M6 |

Function activates only when Tool Changer M-function (M6) activated. |

|

Both |

Function activates when a tool number or M6 is activated. |

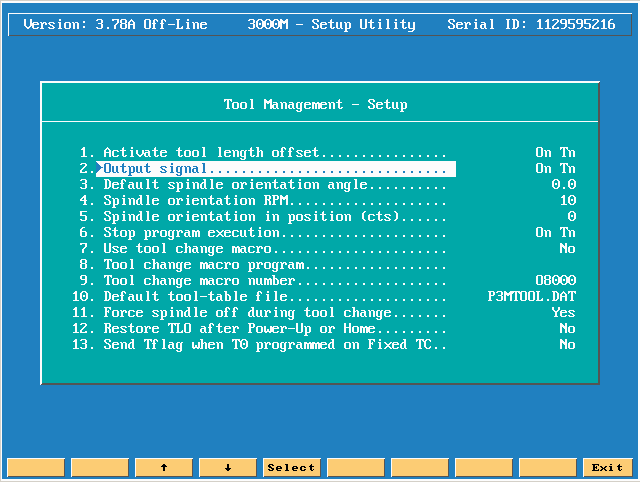

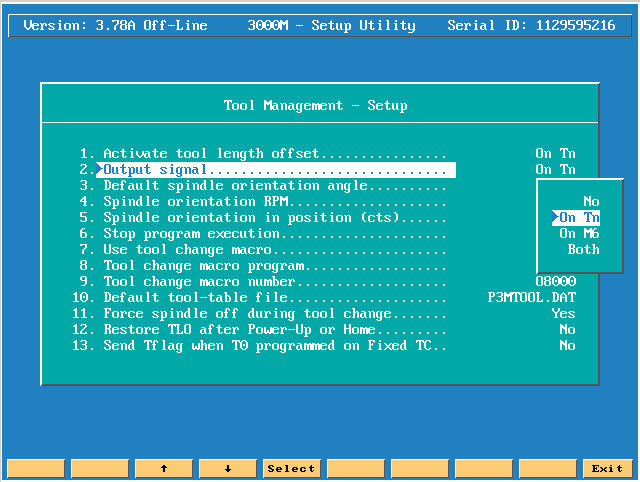

Move down and press enter on Output signal.

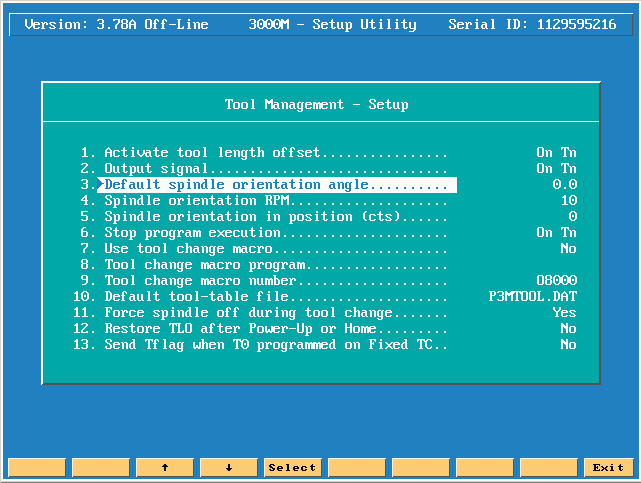

Move down to Default spindle orientation angle.

Select an angle of orientation beyond the marker pulse. The range is 0.1 to 360 degrees. This feature eliminates the need for exact mechanical positioning of the spindle encoder.

The spindle orientation angle is programmable via CNC software. [Default: 0.0] Valid range: (0.1–360.0)

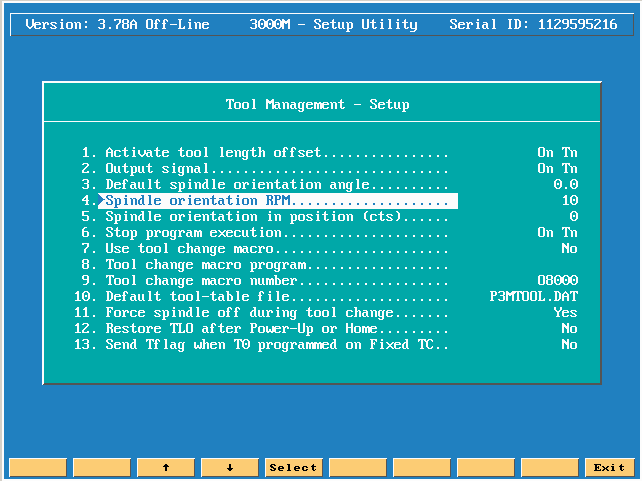

The next line down is Spindle orientation RPM.

Specifies the orientation RPM of the Spindle. Consult relevant spindle drive documentation for proper Spindle speed encoding and appropriate orientation speeds.

Maximum programmable orientation spindle speed is 250 RPM. [Default: 10] Valid range: (1–250).

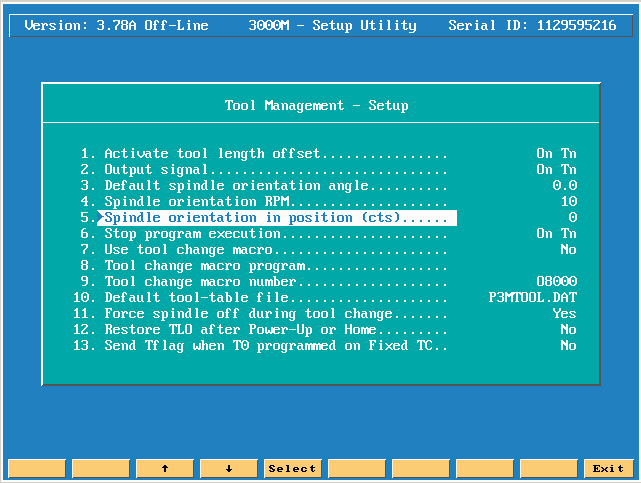

The next line down is Spindle orientation in position (counts).

At the end of a spindle orientation sequence, the system checks for the spindle position to be within this parameter range. If spindle position is within the counts (cts) range, the system completes the orientation sequence. If not within the count range, the system waits until the spindle is within the in position range to complete orientation.

[Default: 0 (counts) No in position check] Valid range: (0–50).

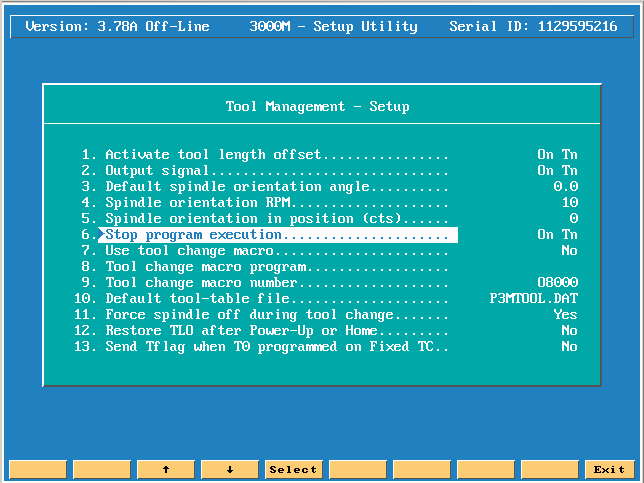

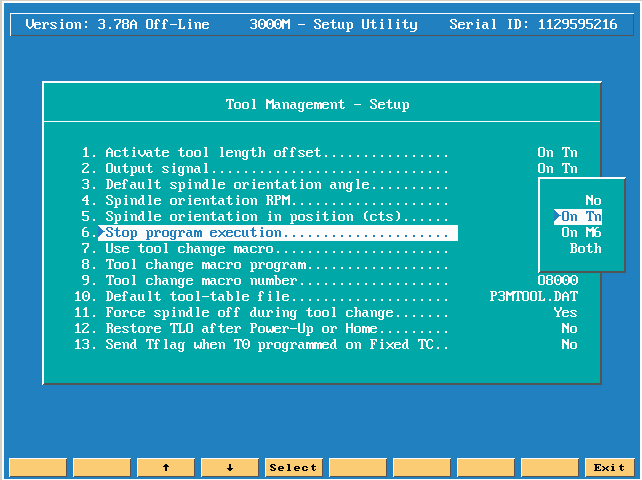

The next line down is Stop program execution.

Use this feature to halt program operation on Tn commands in order to give the operator time to change the tool.

Press START to resume program operation.

[Default: On Tn]

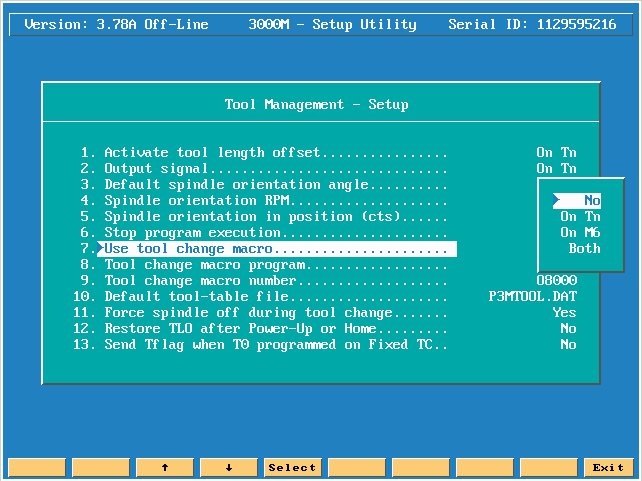

The next line down asks if you want to use a tool change macro that you write or the builder wrote.

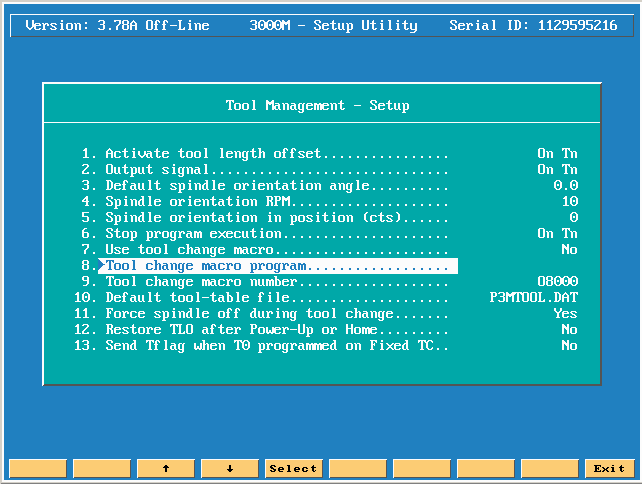

If you answered anything other then NO for the previous question, then a Tool change Macro will be used.

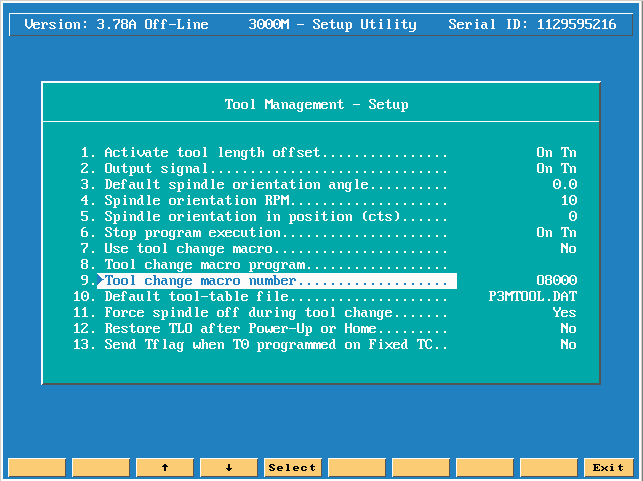

The next line down is Anilam’s default Tool Change macro number O8000.

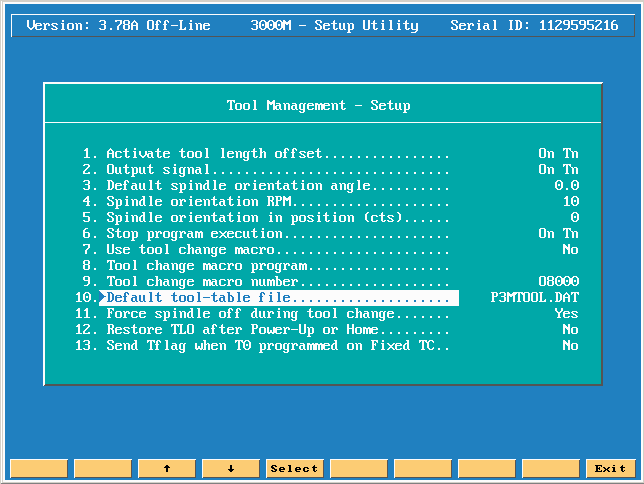

The next line down is for the Anilam default Tool library file name.

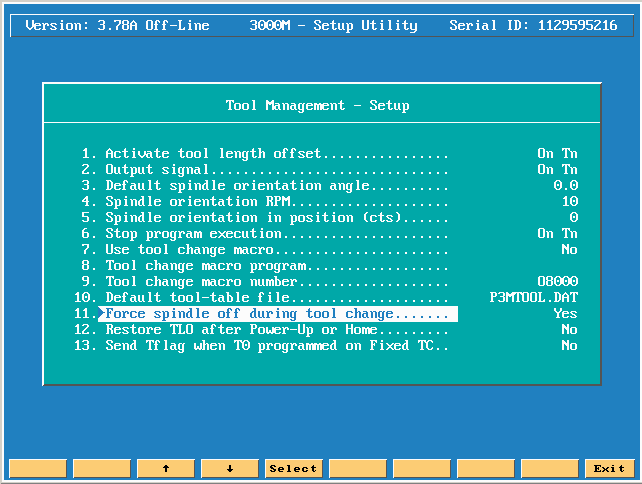

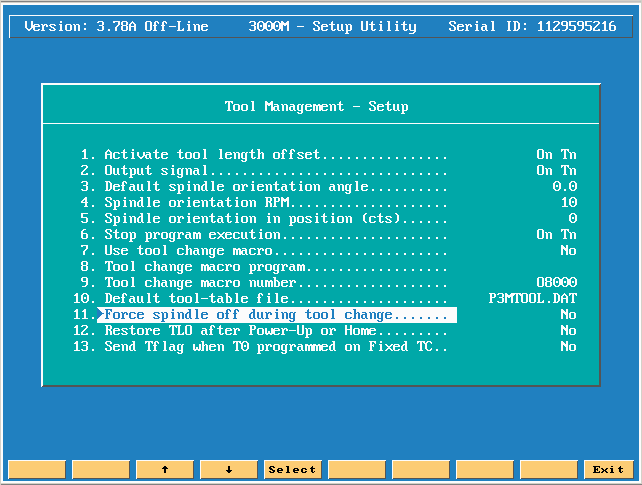

The next line wants to know whether to turn the spindle off during a Tool Change either Yes or No.

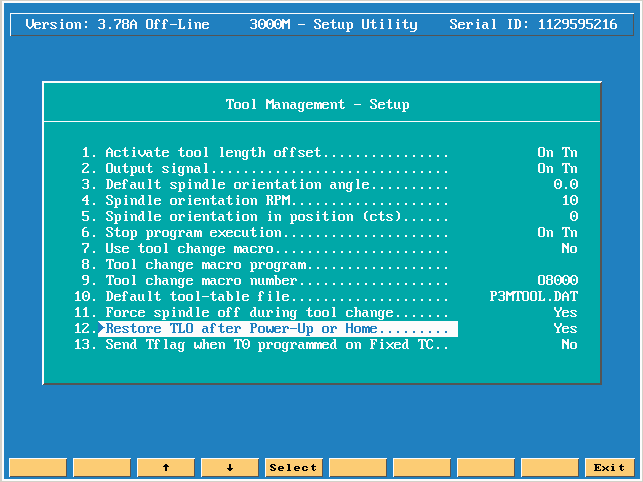

The next line down wants to know should the CNC restore the TLO (Tool Length Offsets) after Power-up or Home, Yes or No.

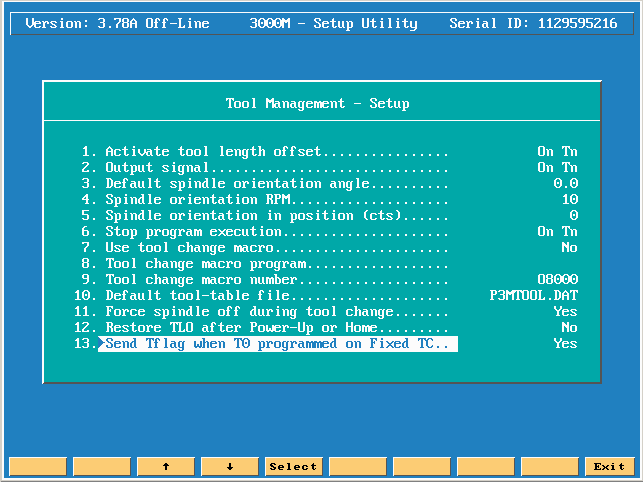

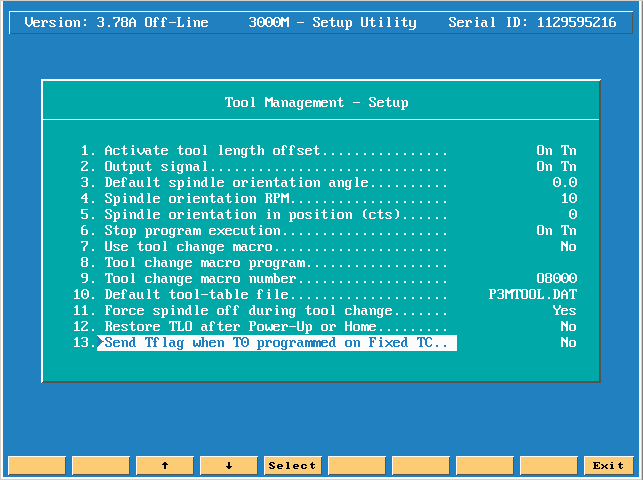

The last line wants to know to have the CNC send a Tflag (Tool flag) when a T0 programmed on Fixed TC Yes or No?

When flag is set to No, T0 is not sent to the IPI.

When set to Yes, whenever a T0 is executed, the Tflag is sent to IPI with a value 0.

[Default: No]