Miscellaneous setup info:

Press the enter key on the Miscellaneous option.

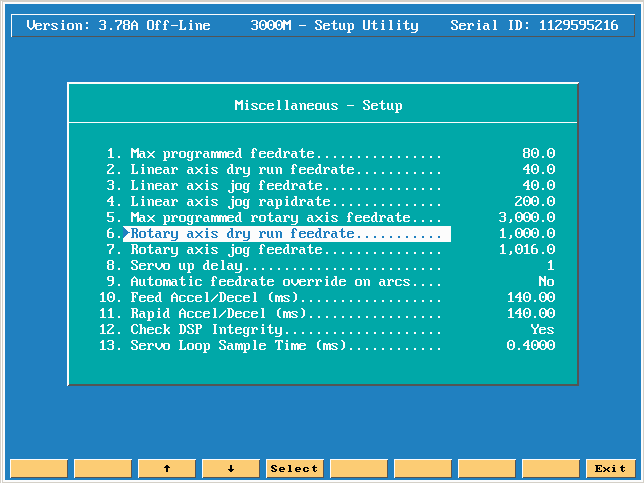

If you want to change the Maximum allowable programmed feed rate value, then press the enter key and type in the new amount.

The Default is 80 IPM. If you try to enter in for instance 100 IPM, the CNC won’t let you because the max is currently 80.

The next choice down will allow you to dry run the cnc program ignoring the normal programmed feedrates.

In Dry Run Mode, the machine axes (X, Y, and sometimes Z) move through the program without cutting into the work.

The CNC disables coolant operation, and the work may or may not be placed on the table.

Activate Dry Run Mode with M-codes 105 and 106, and deactivate with M107. Dry run feedrates are set in the Setup Utility.

They are often set at greater speeds than conventional feedrates. At the

operator’s discretion, they can be set at any rate.

[Default: 40.0 inches per minute]

|

M-Code |

Function |

Description |

|

M105 |

Dry run on |

Enable machine Dry Run Mode. Program runs at dry run feedrates specified in the Setup, without moving Z-axis. |

|

M106 |

Z Dry run on |

Enable machine Z Dry Run Mode. Program runs at dry run feedrates specified in the Setup. |

|

M107 |

Cancel dry run |

Cancels active Dry Run Mode |

The next choice down Linear axis Jog Feed rate does 2 different things to the CNC.

1st It is the speed when in manual mode and you select a feed jog move using like X+ jog button, it is the feed rate it moves at.

2nd It is the gain break value. By that I mean when you are in the normal CNC screen and you program a feed rate to move an axis, if the feed programmed is at 40.0 inches or less we will run using feed gain parameters and continuous path is active. At 40.1 up to 80.00 you are now using Rapid gain parameters and continuous path is off.

Note: if you want to do High speed machining this is the parameter you increase to allow a feed rate faster then 40 lets say 80 IPM. Now the machine will cut faster and smother but the manual jog for feed will now be 80 IPM!

The next choice down Linear axis Jog Rapid rate is the speed when in manual mode and you use the Rapid jog button like X+ jog button. The Table will move at this speed. This allows the Default rapid speed in a different section to possibly be higher then this.

The next choice down Max programmed rotary axis feedrate sets the maximum speed, in degrees per minute, that a rotary axis may be programmed.

[Default: 3,000.0]

Rotary axis dry run feedrate will allow you to dry run the cnc program ignoring the normal programmed feedrates.

In Dry Run Mode, the machine axes (X, Y, and sometimes Z) move through the program without cutting into the work.

The CNC disables coolant operation, and the work may or may not be placed on the table.

Activate Dry Run Mode with M-codes 105 and 106, and deactivate with M107. Dry run feedrates are set in the Setup Utility.

They are often set at greater speeds than conventional feedrates. At the

operator’s discretion, they can be set at any rate.

[Default: 40.0 inches per minute]

|

M-Code |

Function |

Description |

|

M105 |

Dry run on |

Enable machine Dry Run Mode. Program runs at dry run feedrates specified in the Setup, without moving Z-axis. |

|

M106 |

Z Dry run on |

Enable machine Z Dry Run Mode. Program runs at dry run feedrates specified in the Setup. |

|

M107 |

Cancel dry run |

Cancels active Dry Run Mode |

The next choice down, Rotary axis jog feedrate sets up the feedrate for rotary axes at which the machine travels in Jog Mode.

This defines the machine’s default jog speed for rotary axis.

[Defaults: Feedrate 1016.0]

The next choice servo up delay is designed to keep the CNC from trying to apply the different parameters like backlash comp as soon as the servo reset button is pushed.

If you have a drive board that takes 2.5 seconds to apply power to the motor then you better change this value to 3 seconds!

The automatic feedrate override on arcs is a feature for constant surface speed based on the edge of the cutter. Make sure it always says NO.

If it says yes and you are trying to do a 3 axis spiral or Helical spiral the Z axis will lag behind and not work correctly!

Feed Accel/Decel and Rapid Accel/Decel define Feed and Rapid acceleration and deceleration ramp times (in milliseconds).

[Default: 140.00]

Note: Currently the max you can change this to is 160 for Feed or Rapid Accel/Decel. If you make this any higher you will start to get can node lost errors and the spindle will shut down!

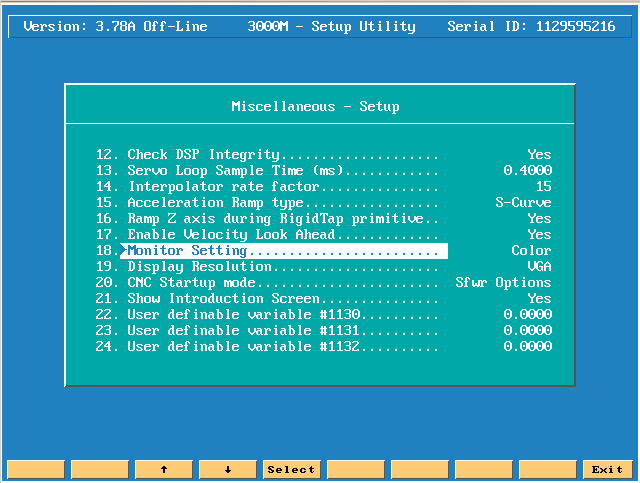

Check DSP Integrity enables (Yes) or disables (No) an integrity check of the DSP Motion Control Board and all commands sent to it from the PC.

[Default: Yes]

You do not want to change this to NO!!

Servo Loop Sample Time (ms) sets the rate at which the servo loop operates (in milliseconds).

[Default: 0.4000]

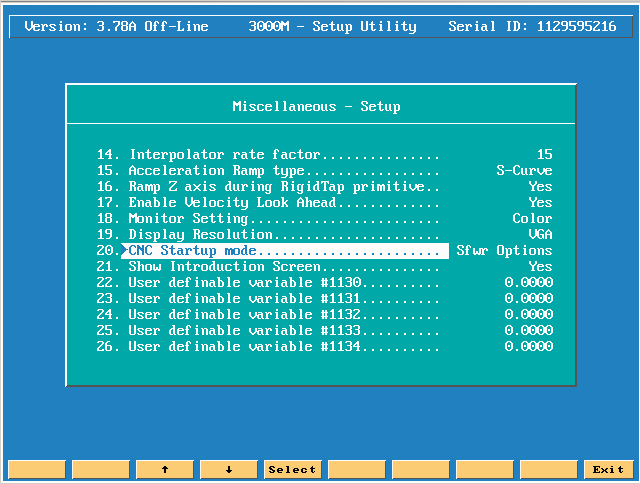

Interpolator Rate Factor allows you to specify the interpolator sample rate (in servo loop time).

[Default: 15]

Selects the Acceleration Ramp type or profile to be used.

[Default: S-Curve]

Bell curve is the original algorithm we designed, it has a lot less CPU overhead needing to be done. If you have a 3D really tiny moves from a cad cam system,

You might find Bell to work better and faster!

Ramp Z axis during RigidTap primitive enables (Yes) or disables (No) the Z-axis profile.

[Default: Yes]

The Velocity Look Ahead parameter is an optimization feature of the DSP motion control firmware. In most cases it should be left set to Yes

(enabled). In applications that run at very slow feedrates and the slow feedrates are not being achieved, the parameter should be set to No (disabled).

[Default: Yes]

Monitor setting has 2 choices Color or Mono.

The Mono setting is for our first Black and white 3200 and 3300 systems!

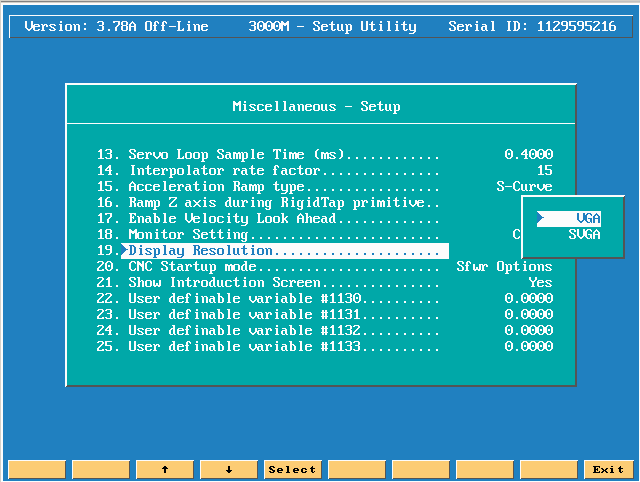

Display resolution has 2 choices VGA and SVGA.

CNC startup mode has 2 choices Software options or Control software.

Show introduction screen Yes or No. If you say NO then you won’t see the Anilam address screen anymore!

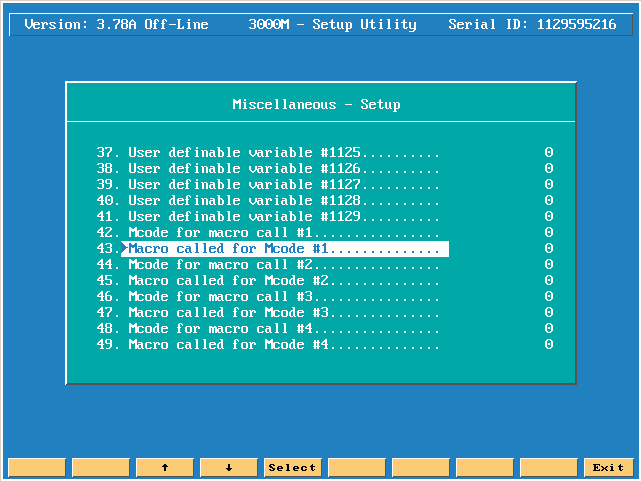

User definable variables are defined via parameters #1130 – #1139 and #1120 – #1129 in Miscellaneous Setup (see Map 6, Menu E, Miscellaneous Setup Menu).

These parameters correspond directly to system variables #1130 through #1139. Parameters #1130 – #1134 are unit based; which means,

these are assigned the units specified for machine parameters (Inch or MM). You can assign parameters #1135 –#1139 and #1120 – #1129 only number values.

A typical usage of these variables would be to define the tool-changer

height in a tool-change macro. By using a user definable variable, the

height of the tool-changer can be adjusted without editing the macro itself.

See “Tool Changer Macro Example.”

#1130 – #1139 [Default: 0.0000]

#1120 – #1129 [Default: 0]

M-Code number you assign to call the macro in “Macro called for Mcode

#1 – #10.”

[Default: 0]

The macro number that is called when the M-Code in Mcode for macro call #1 – #10 is executed.

[Default: 0]