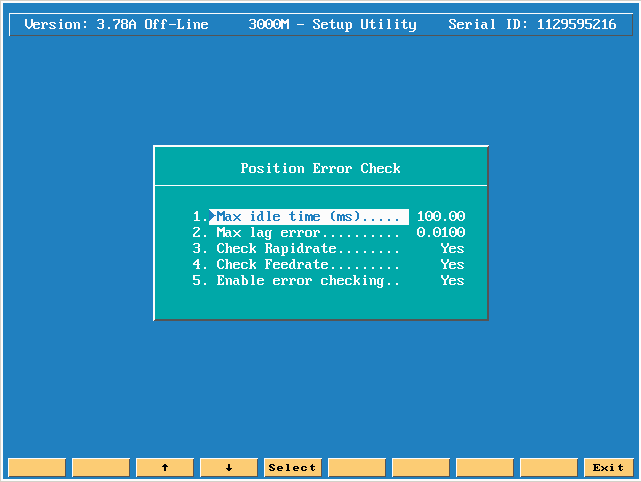

Position Error Check setup info:

Press the enter key on Position Error Check.

Refer

to ![]() Table 2-4 for

definitions of these parameters. If the PEC algorithm detects a fault, the

servos shut off, and one of the following messages appears:

Table 2-4 for

definitions of these parameters. If the PEC algorithm detects a fault, the

servos shut off, and one of the following messages appears:

“ERROR: (AXIS) LAG OVER MAX!”

“ERROR: LOST (AXIS) FEEDBACK!”

WARNING: The Position Error Check parameter must be enabled for the CNC system to be able to declare a servo fault and shut down the system in an emergency.

The CNC detects a loss of motion and declares an error via the Position Error Check (PEC) algorithm. The variables of these calculations are configurable.

|

Position Error Check Parameter |

Definition |

Default value |

|

Max idle time (msec) |

the internal command for a move and the input of counts from the feedback device, signifying motion. |

100.0 msec |

|

Max lag error |

The error distance allowed at rest or low feed rates, before declaring a fault. |

0.0100 |

|

Check Rapidrate |

Enables rapidrate test. This test checks the feedback during rapid moves to see if the axes are reaching the programmed rapid rate. Ensures that machine is reaching its full programmed rapid rate; if it does not, an Error Message displays. |

Yes |

|

Check Feedrate |

Enables feedrate test. This test checks the feedback during feed moves to see if the axes are reaching the programmed feed rate. Ensures that machine is reaching its full programmed feed rate; if it does not, an Error Message displays. |

Yes |

|

Enable error checking |

This setting is used to enable/disable Position Error Checking (PEC) for troubleshooting or comparison. CAUTION: You must enable the PEC parameter for the CNC to declare a servo fault and shut down the system in an emergency. |

Yes |