Control software setup info:

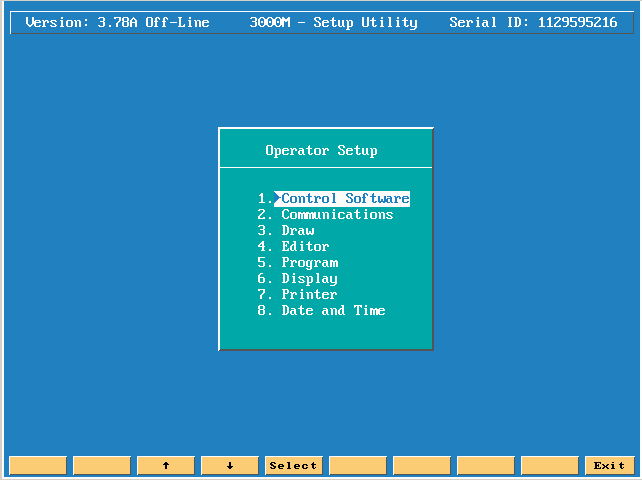

Press the enter key on Control Software.

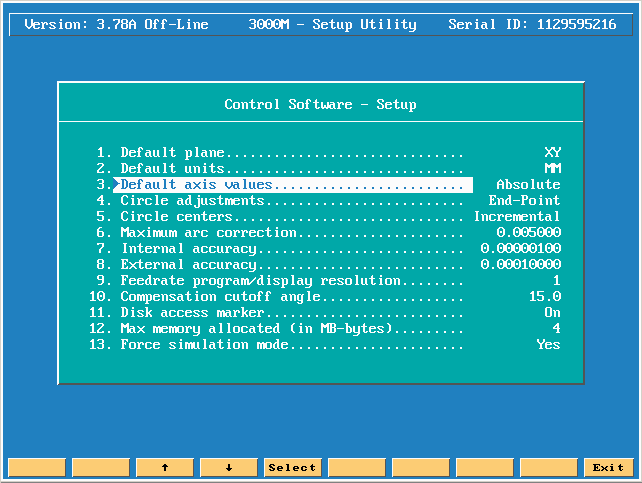

The default plane choice sets up which plane you want to program in when the CNC first starts up. At any time in CNC mode you can change the plane that you want to program in.

Below are your choices for the Default plane.

Default units screen allows either the operator to initially write programs in the INCH mode or MM mode see below.

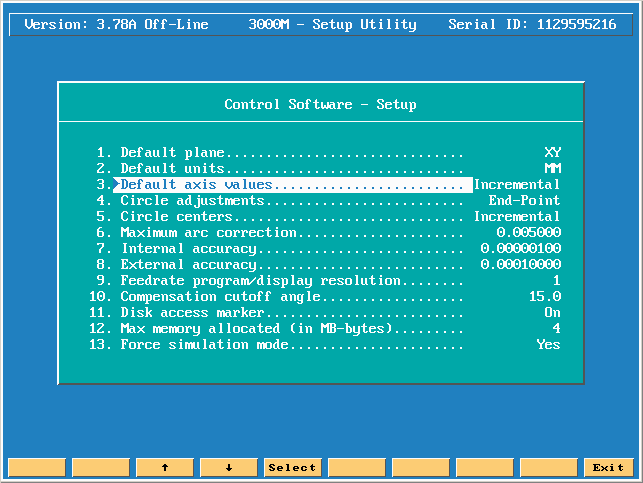

Default axis values screen allows you to setup either absolute or incremental program as the default, you may however at any time in the CNC screens change to one or the other.

Circle adjustments choice allows the cnc to automatically adjust the circle to either ENDPOINT or adjust the circle CENTER point.

Usually you want to adjust the end point if you are using a cad cam program to create the arc!

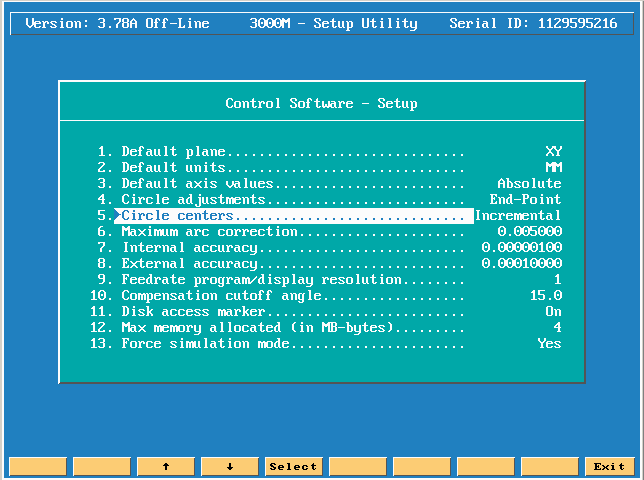

The circle centers choice has a couple of options incremental, absolute or modal:

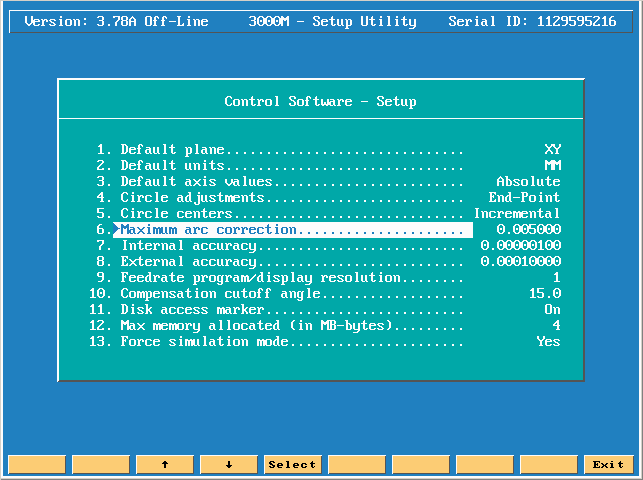

Maximum arc correction is used to let the operator know that the CNC has changed the circle either end point or center to allow for the start and end points of the arcs to blend.

The value of .005 is just the threshold point that the CNC tells the operator that the arc was modified and its adjustment was greater then .005 inch.

Changing this value will not correct anything! It just lets the operator know of the pending problem!

Internal Accuracy choice is used to allow the CNC to verify while in a program if the programmed tool path and the calculated tool path using cutter comp can allow the cut to occur.

If you increase the number to .00000001, this will allow the CNC more time to make sure we can actually fit into the desired area using the specified cutter and path.

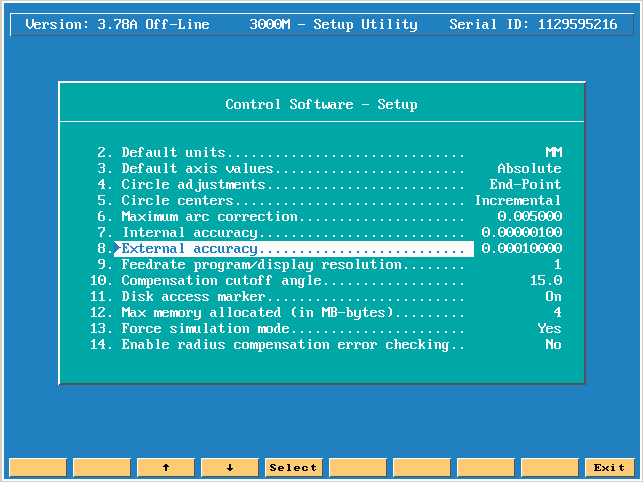

External Accuracy Maximum accuracy obtainable on a given machine (machine resolution) NOTE do not change this value ever!!

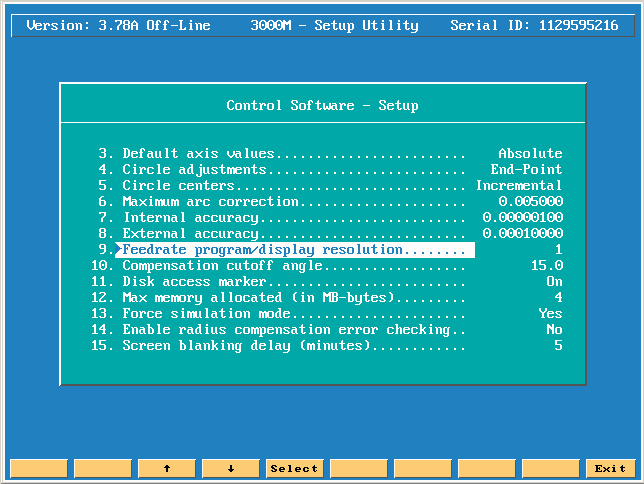

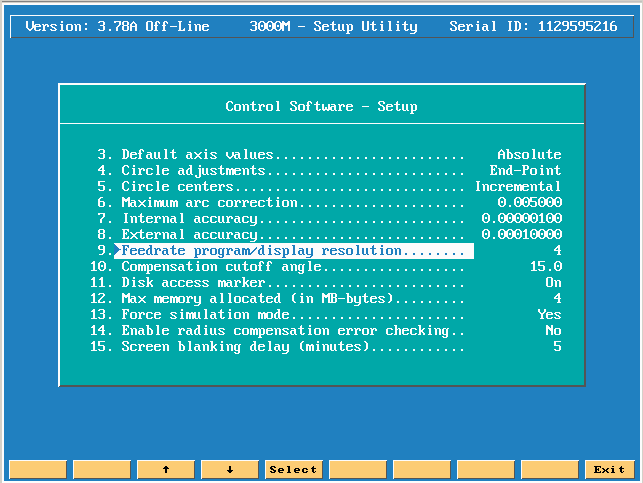

Feedrate program/display resolution, shows how many decimal places to the right choices between 1 and 4 places.

Compensation cutoff angle prevents or reduces wasted travel on acute angle. (Refer to Figure 3-1, on page 3-4 in manual 70000499 Compensation Cutoff Angle.)

Disk access marker when the CNC is reading/writing information from/to a disk or other medium, the disk access marker appears in the upper-left corner of the screen. The disk access marker looks like a small arrow. The default is ON.

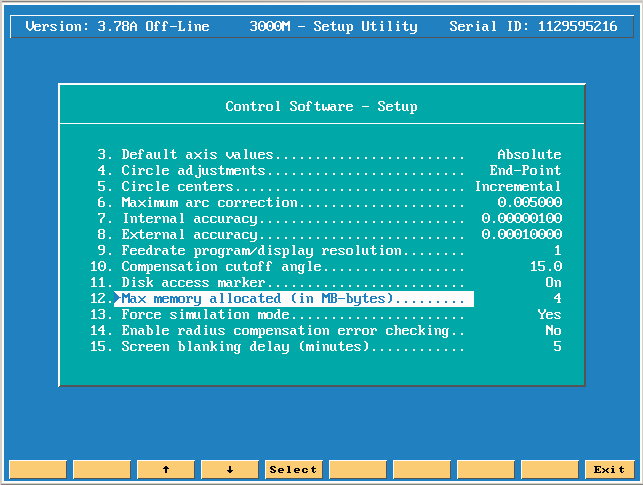

Max Memory allocated represents the amount of memory the CNC will use for running a program. If the program you are trying to edit is larger then this value, you will not be able to edit the file unless you change this parameter. The larger you make this value the slower the editor will load because it must make sure that the amount of memory you say here in this parameter is actually available to use.

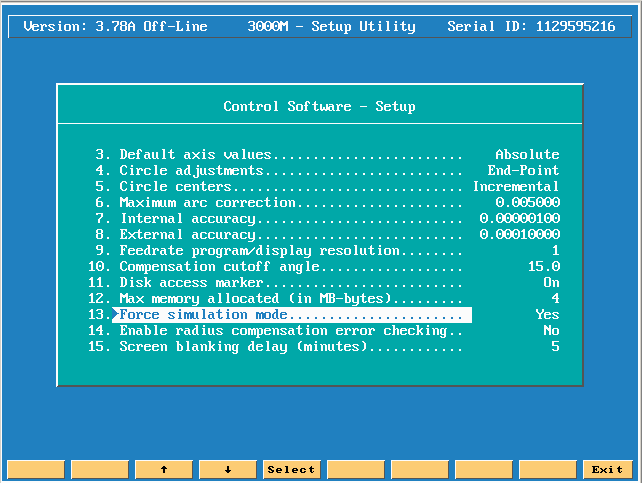

Force simulation mode on the CNC it must be NO, on offline software it will be YES.

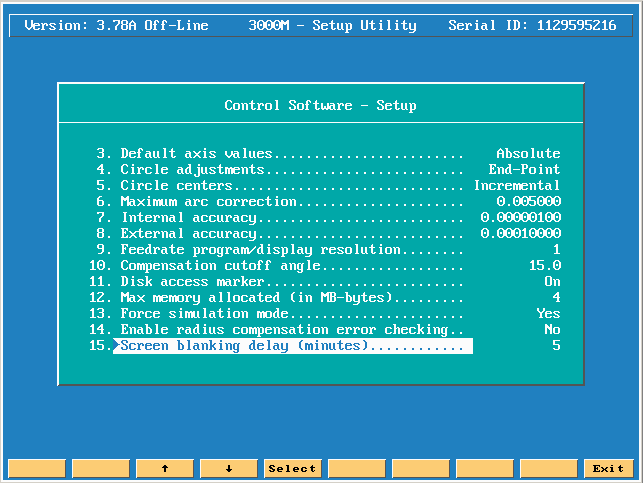

Enable radius compensation error checking is a LATHE feature leave it set to NO!

This activates the tool radius compensation error checking. The error checking is designed to eliminate simple gouges caused by overcompensation.

Screen blanking delay sets the time duration before the CNC will change into the screen blanking mode. NOTE putting a value of 0 will keep this feature from going to screen blank mode this is used at shows so this feature will be deactivated.